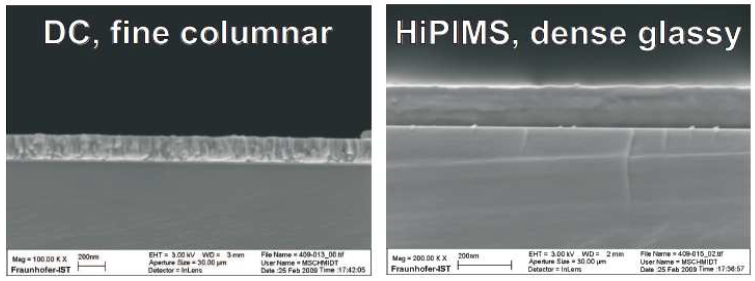

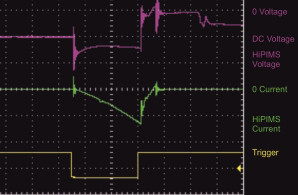

HiPIMS processes are known for increasing the ionization rate of the sputtered species, thus enabling the magnetron sputtering technology with a very flexible tool for film properties engineering. Optical emission spectroscopy (OES) measurements have detected up to double ionized ions during the high power pulse of the plasma. However, one of the disadvantages of HiPIMS has been a decrease in the power-normalized deposition rate.

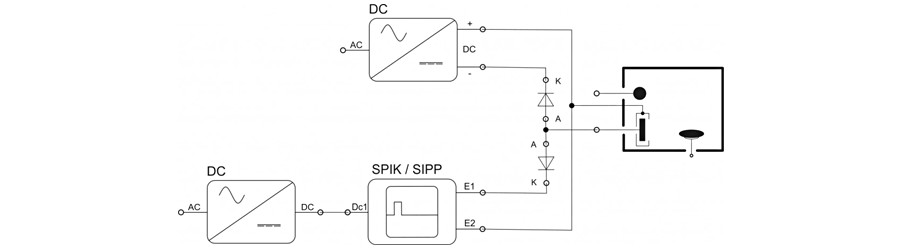

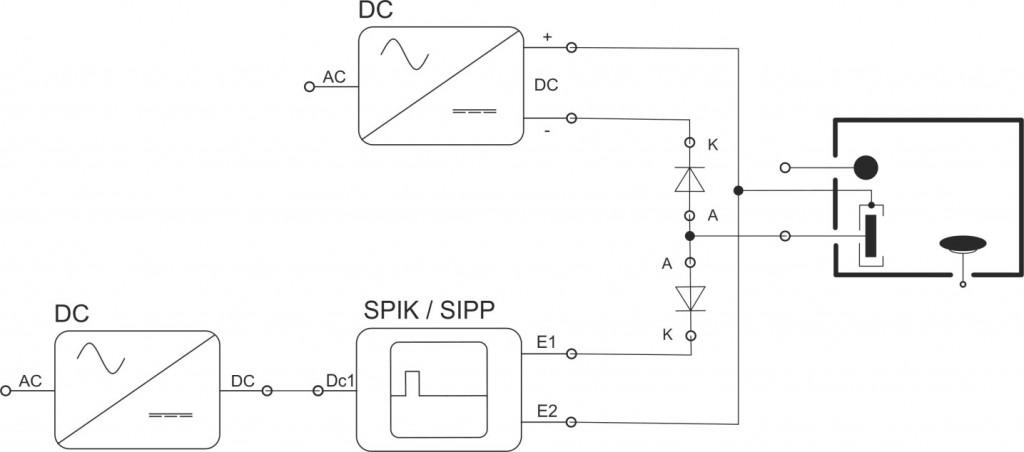

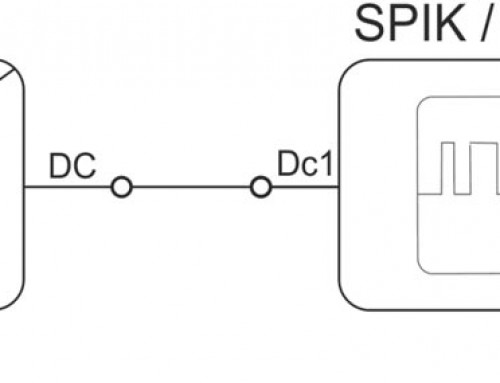

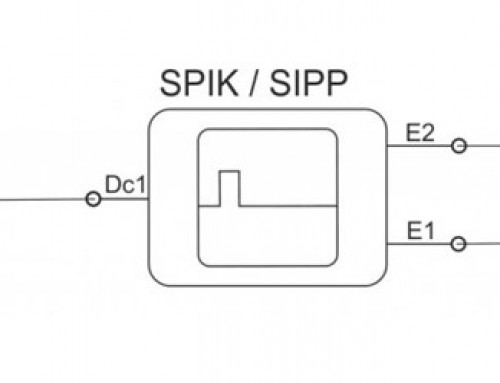

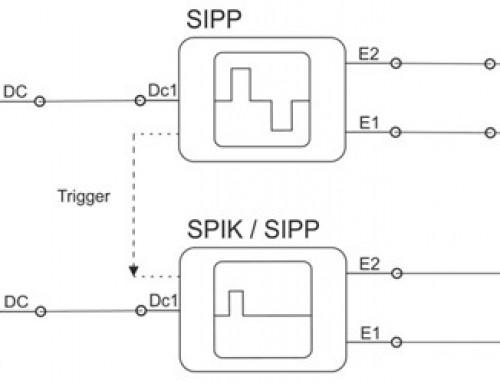

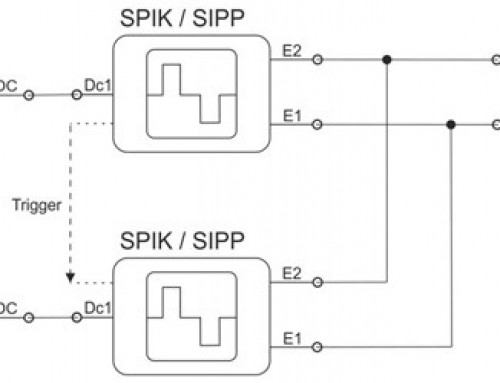

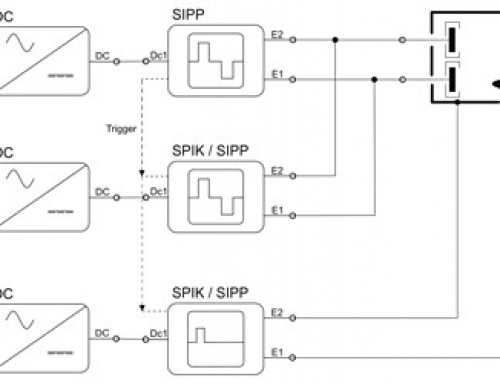

Using a diode matching network the DC power of an additional DC power supply unit can be superimposed to HiPIMS pulses, in order to increase the deposition rate The HiPIMS+DC superimposed application is a simple way to retrofit existing DC sputter processes with a HiPIMS (Unipolar) generator. The two diodes work like an automatical switch between the DC source and the HiPIMS source.